Real-Time Optimization of Completion Design Using Seismos Acoustic Friction Analysis (SAFA)

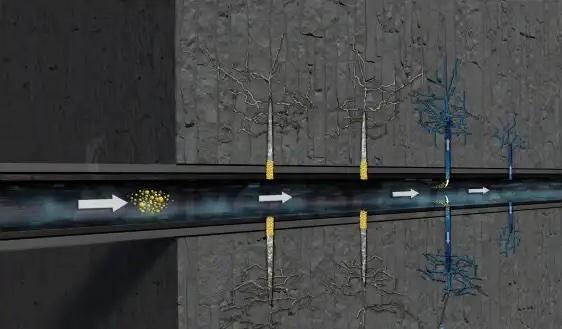

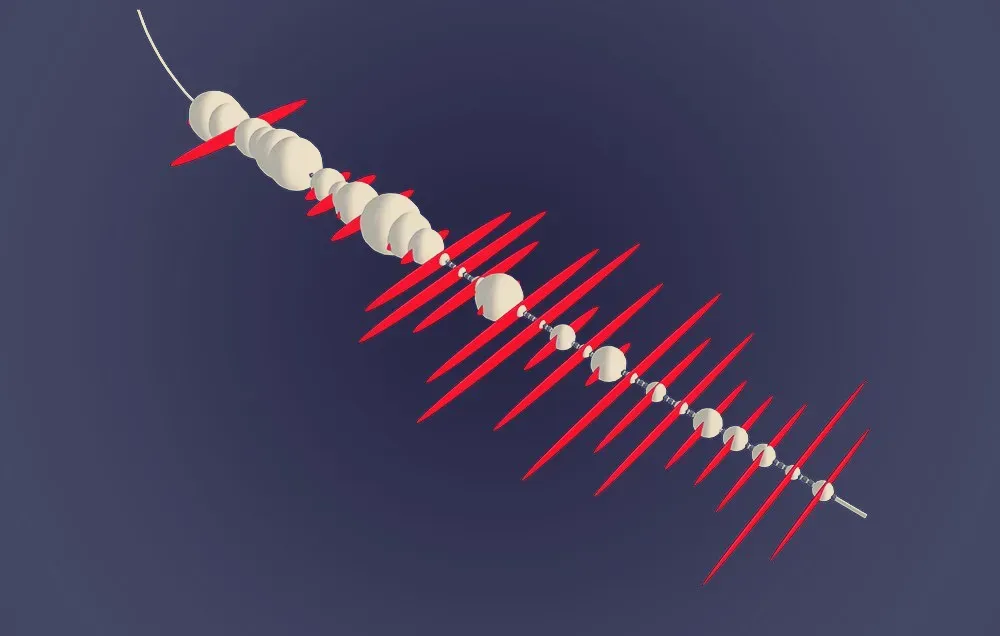

Unconventional reservoirs demand unconventional insight. Historically, operators have optimized perforation schemes, fluid composition, and pumping strategies by relying on delayed diagnostics or post-job evaluations. Seismos Acoustic Friction Analysis (SAFA) changes that paradigm, bringing real-time, surface-based fracture performance data directly into the decision-making process.

A Field-Validated Approach to Fracture Optimization

In this case study, Seismos deployed SAFA across a 60-stage lateral, providing continuous feedback on fluid entry and cluster efficiency. SAFA uncovered substantial differences in fracture performance early in the job, enabling the operator to modify treatment designs mid-fracture.

Key Findings from the Field:

- Initial Fluid Distribution: SAFA data showed a Uniformity Index (UI) as low as 0.45 in the early stages—indicating highly uneven fracture growth and poor proppant distribution.

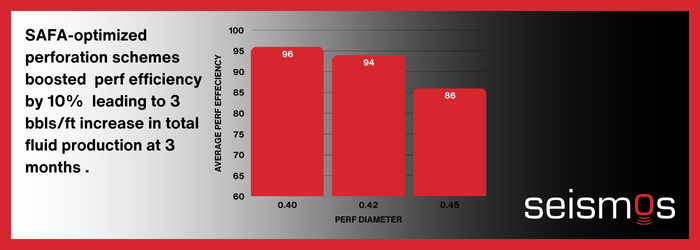

- Treatment Optimization: Mid-job, the operator increased perf efficiency by 10% based on SAFA feedback.

- Performance Gains: In just three months the operator saw 3 bbls/ft increase in total fluid production.

- Operational Efficiency: These changes were implemented in real-time, requiring no operational logistics or equipment change.

Why This Matters

These results are not theoretical—they're field-proven. SAFA provided a closed-loop system in which design changes were informed by real-time downhole conditions and immediately validated for effectiveness. That’s a new standard for unconventional completion diagnostics.

Seismos is leading the real-time revolution in fracture QAQC. Our non-invasive, surface-based technology allows you to validate and adapt your completion design in real-time—no downhole hardware is required.

Read the full white paper here.

Ready to optimize your next well? Contact our sales team now.