This case study appeared in the July 2018 edition of E&P Magazine

A major operator in Permian Basin asked Seismos to evaluate its treatment effectiveness and completion designs for the lower Wolfcamp A formation. The goals were to identify the types of fracture systems created across the lateral, and how such systems influence production. The project encompassed a two well pad and was completed in early 2018. Each lateral was composed of approximately 45 stages and was treated with a single design.

Delivery

Seismos used its non-invasive equipment suite (Seismos-Frac™) to acquire and deliver real-time data that enabled the operator to make on-the-fly decisions, while having no impact on operations. The instrumentation consisted of a proprietary sensor and source connected on the wellhead.

By sending a series of pulses down the fluid column at specific times during the treatment, Seismos remotely interrogated the subsurface for each stage. Various wellbore properties, near wellbore fracture conductivity, network complexity, effective propped fracture length, and far-field fracture network connectivity to the reservoir were computed.

Description of Findings

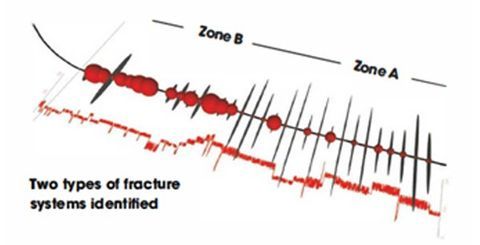

In addition to Seismos’ measurements, Sonic Logs, Tracers and Geochemical data were collected. Sonic logs and Geochemical data indicated two different zones (A & B) across the lateral of the subject wells.

The pump design resulted in the development of two distinct types of fracture systems with significantly different characteristics. Seismos' measurements identified a fracture system with two-times higher near-field complexity and conductivity values in zone B, compared to the fracture system developed in zone A of the lateral.

Seismos-Frac™ technology also found that the near-wellbore complexity had an inverse relationship with the extension of the fracture network. Zone A, while a less complex fracture network, had a 32% larger average effective propped fracture length compared to zone B.

Impact on Production

Zone A covered 50% of the lateral and had significantly higher hydrocarbon content than zone B; however, zone B had an overall higher brittleness index.

Tracer data provided additional insights for the production performance of the two facture systems. Despite having significantly lower hydrocarbon content than zone A, zone B was producing over two-times more hydrocarbons on an average stage basis (tracer data, 90 days).

Lower hydrocarbon quality rock yielding higher production was attributed to the development of an enhanced near wellbore complexity system, which was accurately measured by Seismos and supported by the geomechanical rock properties.

Conclusion

Seismos-Frac™ unlocked an understanding of the stimulated fracture systems developed across the lateral, measured with precision their extended reservoir connection, and identified the near field conductivity and complexity as the dominant production drivers. Correlations with Sonic Logs, Tracers, and Geochemical data proved that Seismos-Frac™ empowers operators to enhance production contributions of each stage.