MWF™

Measurements While Fracturing

What's MWF?

Real-time Quality Control Agent for Fracturing

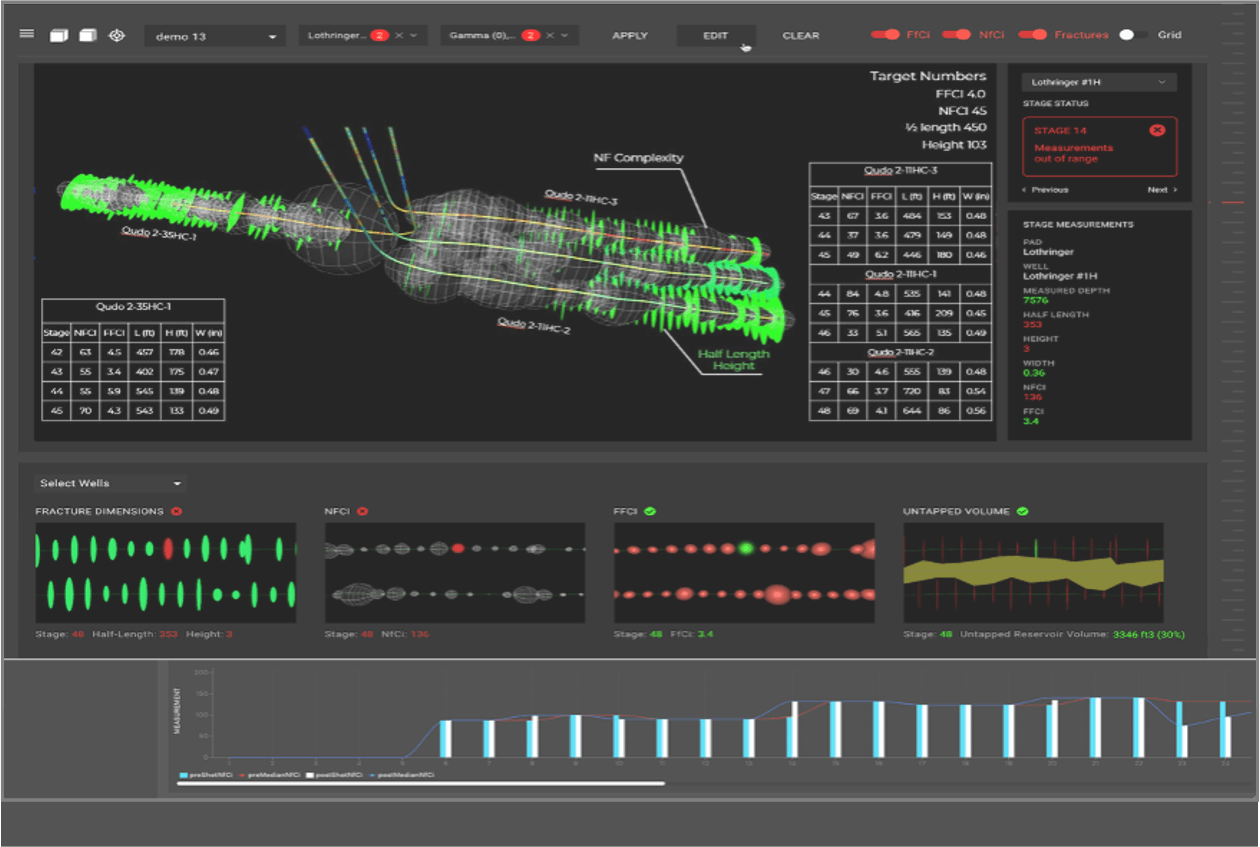

Seismos MWF™ extends beyond fracture diagnostic technologies, displacing the need for fiber optics by introducing a plug-and-play system that seamlessly connects to the wellhead and uses acoustics and AI to continuously monitor each stage's stimulation performance.

Operational advantages:

No need for fiber optics

1502 connection to wellhead

Continuous monitoring behind the scenes

Real-time prompts

Applications

Can't improve what isn't measured

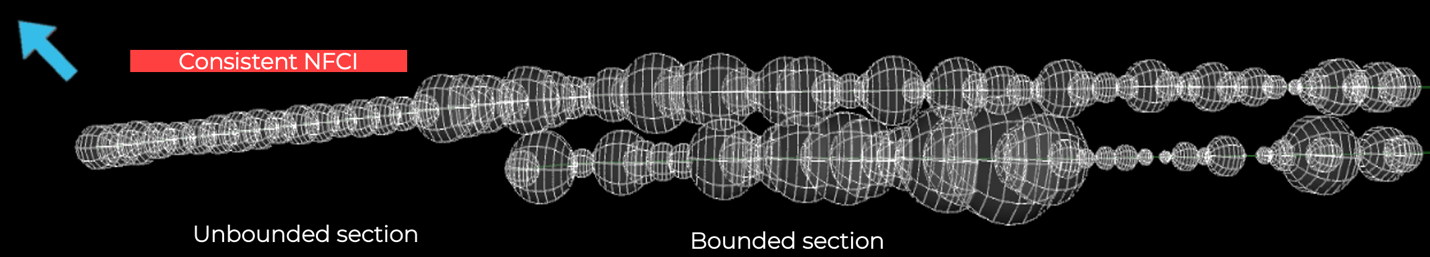

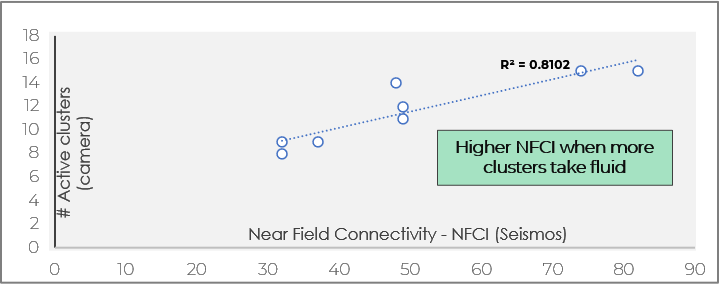

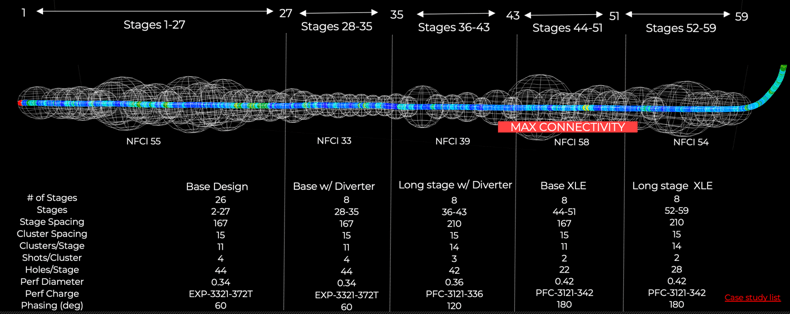

The Seismos MWF ™ (Measurements While Fracturing) Quality Control system embeds a one-of-a-kind measurement referred to as NFCI (Near Field Connectivity Index). NFCI is a patented measurement of the reciprocal of flow resistance (NFCI = 1/flow resistance) in the near wellbore area. The higher the NFCI, the higher the ability of the fracture network in the near field (near wellbore) area to allow hydrocarbon inflow into the wellbore.

Maximize near wellbore stimulation

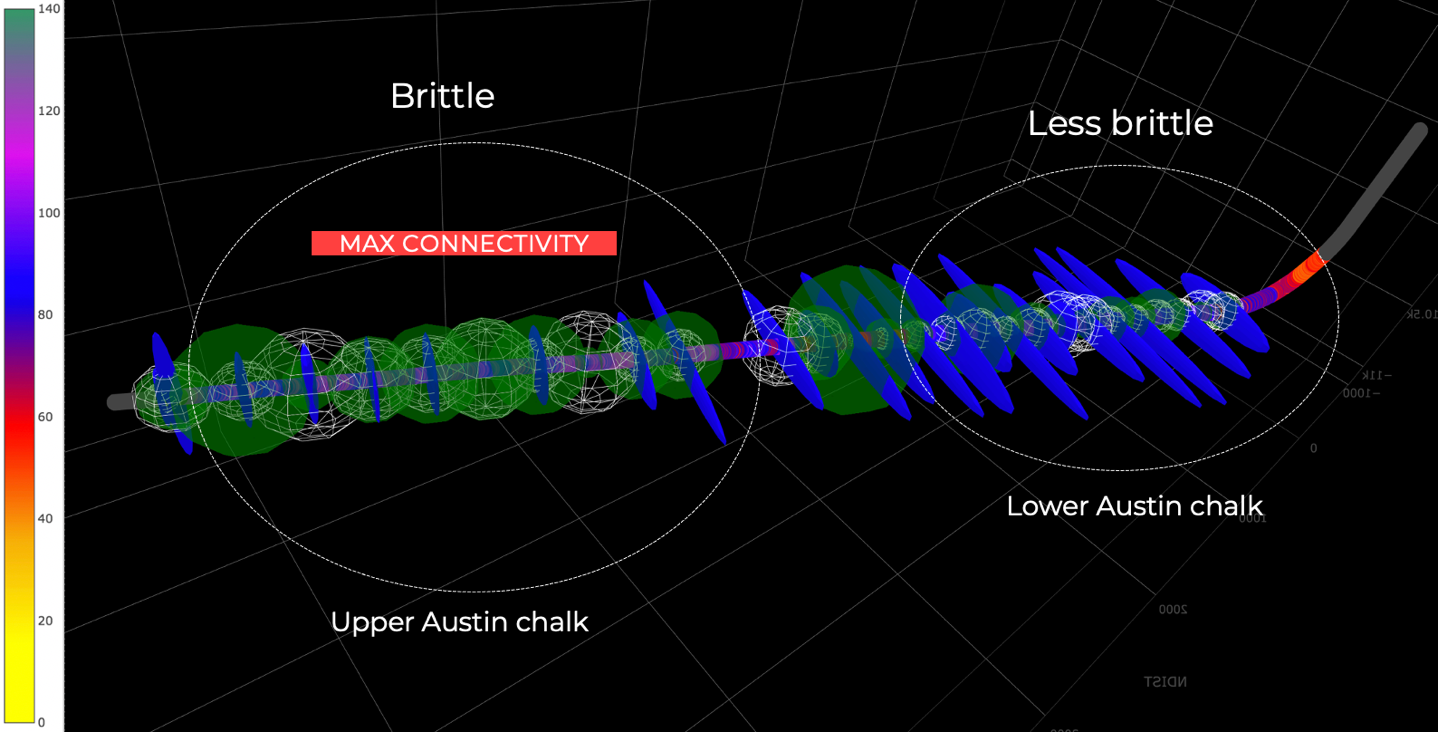

Identify optimal/suboptimal connected fracture systems

Understand far field fracture geometry

Influencers

NFCI sensitivities to stimulation treatment, geology,

and stress interactions

A critical advantage and differentiator of NFCI is the high sensitivity to critical parameters such as stimulation treatment, geology, stresses, and number of clusters taking fluid.

Below are some examples visualizing such differences:

TREATMENT

Varying stimulation design parameters (cluster design, perforation design, stage spacing, and so on) has a material effect on fracture system properties, and how such changes in fracture system properties are captured by the NFCI measurement.

Features

Turning each well into a winner

Complete Optimization

Establish maximum Near-Field Connectivity on a uniform stage-to-stage basis

1. Adjust frac sequence to control stress interactions

2. Establish sufficient connectivity to the reservoir

3. Enable lateral stimulation consistency

Test Designs

Quality Assurance